Discover the dry ice cleaning solutions

Dry ice cleaning has been developed as an alternative, efficient, fast and environmentally friendly method of cleaning for virtually any type of material.

The dry ice blasting machines, proposed by Ikaros, have a technology patented by CRYONOMIC®, a leading Belgian company in the production and design of dry ice cleaning equipment, successfully used worldwide since 1992.

What is dry ice blasting and how it works?

An effective, fast and ecological cleaning!

Dry ice blasting is an alternative method of cleaning, and sometimes the only solution to specific needs, especially in the technical-industrial sectors.

When it is necessary to carry out cleaning in environments or places where there are machines or surfaces that require a not abrasive but still intensive cleaning, opting for traditional cleaning methods can provoke a number of problems.

It is advisable to evaluate them before proceeding, in order not to be faced with unsatisfactory results or to realize after that the method applied has been too ‘aggressive’, resulting in a clean but damaged surface.

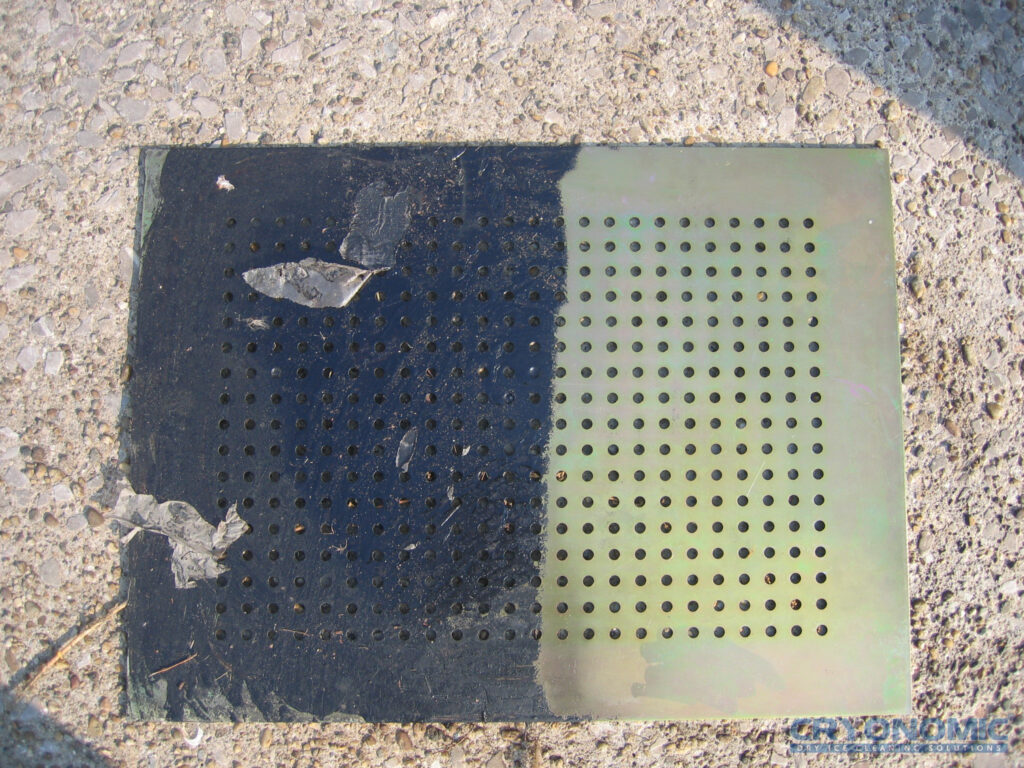

The dry ice blasting, or CO2 blasting, is a technique similar to the classic sandblasting, its main difference being the solid form of carbon dioxide (CO2 ), called pellets.

In fact, it is a cleaning process that takes place through a thermal shock, removing the dirt in a quick and effective way without damaging the surface. The tiny CO2 pellets are propelled at high speed and then disappear in the form of gas without leaving any residue, unlike other methods.

A wide range of applications…

Maintenance of machines: packaging machines, production lines, core boxes, conveyors

Cleaning of permanent, injection, compression and blow moulds, ovens, extruders and filters

Removal of glues, resins, greases, carbon deposits, asbestos

>> Watch the animation clip to find out more about dry ice blasting!

Dry ice blasters and all necessary equipment for cleaning with CO2!

Ikaros offers a range of dry ice blasters available in two different series according to your needs.

Find out more about the unique characteristics of two series for dry ice cleaning:

COB series (COB62, COB62plus, COB71, COB71R): single hose dry ice blaster for hard cleaning (ex. Removal of, paint, asbestos, cleaning facades, restoration and renovation);

Do you want to read more? Download the COB serie leaflet of CRYONOMIC®COMBI series (COMBI71, COMBI72, COMBI73): double hose dry ice blaster for high performance cleaning results.

Do you want to read more? Download the COMBI serie leaflet of CRYONOMIC

Blaster equipments and accessories:

Nozzles and blast guns

Set of hoses:

- heavy duty blast hose with quick coupling and stainless steel earthing

- one control cable (for start/stop, gun light and optional remote control on the gun!)

- protecting sleeve

Dry ice or air-only blasting option

Dry ice boxes

Pelletizers

The advantages of CRYONOMIC® dry ice technology compared to traditional cleaning methods:

O: advantage sometimes applicable for this technique..

X: advantage not applicable for this technique.

| Cryonomic | Sand Blasting | Solvent Cleaning | Hight Pressure | Manual Cleaning | |

|---|---|---|---|---|---|

| Time Saving: |

|||||

| Cleaning in the production environment | V | X | O | X | O |

| No need to strip down the production machines | V | X | X | X | X |

| Short o no production stop | V | X | O | X | O |

| Fast cleaning method | V | V | X | V | X |

| Environmentally friendly: | |||||

| Generates no additional waste | V | X | X | X | X |

| No use of aggressive or dangerous products | V | X | X | X | O |

| No noise pollution | X | X | V | X | X |

| Other advantages: | |||||

| Leaves the substrate intact | V | X | O | O | X |

| Suitable in food industry | V | X | X | V | O |

| Pellets do not conduct electricity | V | X | X | X | O |

PUT US TO THE TEST!

Contact us to request a demo or to receive further information.